Since purchasing the kit I've done my homework getting the right materials and information to make building the switches I'll need as easy as possible while I learn the methods.

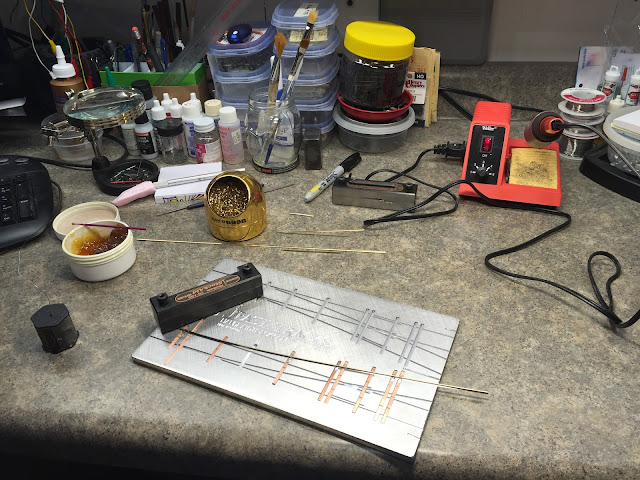

I upgraded my horrible old Radio Shack soldering iron to a Weller WLC100 stand unit and immersed myself in handlaying track videos such as the Fast Track series on Youtube or Tony Koester lending a hand with the trackwork on Model Railroader's Winston-Salem Southbound project.

Only two things caught me off guard as I started; the need to run out and buy a new mill file as mine was old and no longer very sharp and my soldering flux had aged to the point I should go get a new bottle soon.

Otherwise everything went as smooth as I could've hoped. If you know anything about the Fast Track system then you probably saw that statement coming, but if you're like me and felt like handlaying track was some sort of Voodoo magic, give it a try. You might be pleasantly surprised at the results.

|

| Starting the first stock rail. |

|

| Brendan capturing Dad concentrating intently on his work. |

|

| Checking my work, rolls smooth! |

|

| I figured my first one would be ugly enough for a hidden staging yard but it's not too bad. One down, probably another four dozen to go... |

Chris,

ReplyDeleteVery nice looking turnout! Wouldn't banish that turnout to hidden staging at all!! Brendan did a good with the picture, too!

Tim Moran

Thanks Tim! building one of these was a real confidence boost for the future trackwork. I might be looking to borrow that #8 pointform tool sooner than I thought!

DeleteI agree, it looks very nice. The frog looks great. It'll look even better when you get some QuickSticks attached to it and it is down on the layout with ballast.

ReplyDeleteIf you go to Home Depot get either the Nicholson or Corona mill files and you probably want smooth cut (finer teeth) instead of bastard cut (coarser teeth). They are made in Mexico these days but they are still decent files. I have some mill files that are all about 35+ years old but they are still nice and sharp. You can borrow one if you would like.

Thanks Jeff! I think I'll keep pumping them out then pick the worst looking ones to use in the first staging yard to get built.

DeleteYep, Home Depot is where I bought a Nicholson 10" Bastard cut which works just fine. I recall your offer from the other day and I wouldn't mind trying one of yours out.

I just finished up a second turnout today, knocked an hour off construction time, about 33% lol. Could've been more but I forgot to cut the lines in the PC board ties till I was half way done. I can see getting this down to an hour more or less for each turnout.