|

| Now with the support brackets in place around the corner I can start to figure out curved yard ladder mentioned in the Gas Meter Nuisance post. This may not be so bad after all. |

Wednesday, March 30, 2016

Wordless Wednesday #69

Friday, March 25, 2016

Gas Meter Nuicance

I know I've mentioned it before but it's worth repeating, I hate my gas meter. Well in better terms I'm displeased where it is located.

I'm okay with design deviations of the east end because the real star of the show anyways was the west end of Adena with the wye, bridges, depot and other buildings.

The real problem the meter causes is combining the bump out back into a curve where the east yard ladder starts out of sight to the right of the photo. If the gas meter wasn't there this wouldn't be an issue of course.

The hoppers you see in the above photo barely fit under the meter. So I could go under the meter but I would have to rip out and alter all the benchwork in place to add more clearance for anything else like a boxcar or engine. That's not going to happen at this point. Plus I can't really make that level any lower as that would pinch more space from the lower deck and most importantly part of the laundry area.

I'll figure it out, but I might finally have to turn to a CAD program to do so.

I suppose every layout has at least one major obstacle to overcome. Whether that turns out to be a gas meter, furnace, water heater, chimney, support column or solid wall, something similar is present in almost every layout I've visited so far. Many people could check off that whole list when designing their track plan. Luckily? I only have half that list.

|

| Revenge of the Gas Meter. |

I'm okay with design deviations of the east end because the real star of the show anyways was the west end of Adena with the wye, bridges, depot and other buildings.

The real problem the meter causes is combining the bump out back into a curve where the east yard ladder starts out of sight to the right of the photo. If the gas meter wasn't there this wouldn't be an issue of course.

The hoppers you see in the above photo barely fit under the meter. So I could go under the meter but I would have to rip out and alter all the benchwork in place to add more clearance for anything else like a boxcar or engine. That's not going to happen at this point. Plus I can't really make that level any lower as that would pinch more space from the lower deck and most importantly part of the laundry area.

I'll figure it out, but I might finally have to turn to a CAD program to do so.

I suppose every layout has at least one major obstacle to overcome. Whether that turns out to be a gas meter, furnace, water heater, chimney, support column or solid wall, something similar is present in almost every layout I've visited so far. Many people could check off that whole list when designing their track plan. Luckily? I only have half that list.

Wednesday, March 23, 2016

Wordless Wednesday #68

Monday, March 21, 2016

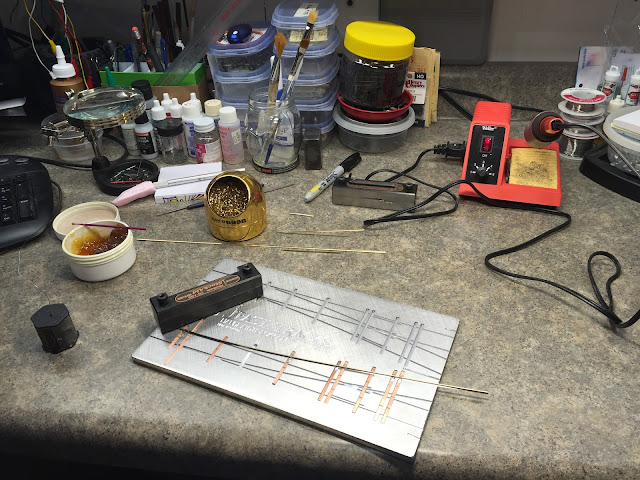

Fast Tracks Turnout #1

A couple of years ago after an overtime filled holiday season, I decided to splurge and buy the #6 switch building kit from Fast Tracks. Fast forward to today with the layout quickly approaching a state where track can begin to be laid, I figured I should finally break out the kit and try it out.

Since purchasing the kit I've done my homework getting the right materials and information to make building the switches I'll need as easy as possible while I learn the methods.

I upgraded my horrible old Radio Shack soldering iron to a Weller WLC100 stand unit and immersed myself in handlaying track videos such as the Fast Track series on Youtube or Tony Koester lending a hand with the trackwork on Model Railroader's Winston-Salem Southbound project.

Only two things caught me off guard as I started; the need to run out and buy a new mill file as mine was old and no longer very sharp and my soldering flux had aged to the point I should go get a new bottle soon.

Otherwise everything went as smooth as I could've hoped. If you know anything about the Fast Track system then you probably saw that statement coming, but if you're like me and felt like handlaying track was some sort of Voodoo magic, give it a try. You might be pleasantly surprised at the results.

Since purchasing the kit I've done my homework getting the right materials and information to make building the switches I'll need as easy as possible while I learn the methods.

I upgraded my horrible old Radio Shack soldering iron to a Weller WLC100 stand unit and immersed myself in handlaying track videos such as the Fast Track series on Youtube or Tony Koester lending a hand with the trackwork on Model Railroader's Winston-Salem Southbound project.

Only two things caught me off guard as I started; the need to run out and buy a new mill file as mine was old and no longer very sharp and my soldering flux had aged to the point I should go get a new bottle soon.

Otherwise everything went as smooth as I could've hoped. If you know anything about the Fast Track system then you probably saw that statement coming, but if you're like me and felt like handlaying track was some sort of Voodoo magic, give it a try. You might be pleasantly surprised at the results.

|

| Starting the first stock rail. |

|

| Brendan capturing Dad concentrating intently on his work. |

|

| Checking my work, rolls smooth! |

|

| I figured my first one would be ugly enough for a hidden staging yard but it's not too bad. One down, probably another four dozen to go... |

Wednesday, March 16, 2016

Wordless Wednesday #67

Monday, March 14, 2016

Construction Report: March 14, 2016

Progress continues with the addition of more shelf supports. Nothing fancy, just reused 3/4" plywood or 1x3s on top of a metal shelf bracket to give the future pink foam top a structure to adhere to.

In one place where I did get tricky and used the slotted bracket system again for extra support on the deep wye scene. I attached some of the supports to each other for added strength. So far I can lean on it and also bang my head stooping under it numerous times without issue...

To finish the corner area I needed a couple more 20" shelf brackets. I luckily found an oddball style on clearance at Lowe's for about 30% off. The only issue was a small hook at their end for the wire shelving system. A cutoff wheel in my Dremel made quick work of these hooks so the wood L-girders could lay flat on top.

And here's how everything fits together from below.

I'm getting to the point where I need to put down the pink foam base to start laying out my track plan for Adena which in turn will help further benchwork development. I've had a small redesign of the east end of Adena Yard to avoid impacting the air rights of the washing machine. It's actually an improvement but it would be easier to accomplish if I had the foam base in place.

In the meantime here are some more photos.

As a side note, the above gas meter has been a pain to design around. Thankfully the gas company came a couple years ago and installed a new unit, so no worries about that happening anytime soon. Still, I'll design the area in front of the gas meter to be removed if the need arises.

|

| The future Adena Yard |

|

| Adena wye bridges area |

|

| Clearance brackets |

|

| Underneath |

In the meantime here are some more photos.

|

| Evil Gas Meter |

Wednesday, March 9, 2016

Woodshop (Wordless) Wednesday #66

Construction slowly continues. Cutting angles in wood can be hit or miss for me sometimes. That being said, I was pretty proud of the way this joint came together.

Wednesday, March 2, 2016

Wordless Wednesday #65

Subscribe to:

Posts (Atom)